Laub/Hunt Packaging Systems – 75 Years of Precision, Performance & Partnership

Laub/Hunt Packaging Systems: Precision, Performance, and Turnkey Excellence

Laub/Hunt Packaging Systems brings over 70 years of experience to the forefront of liquid filling innovation. Their commitment to high-quality engineering and personalized support continues to set industry standards.

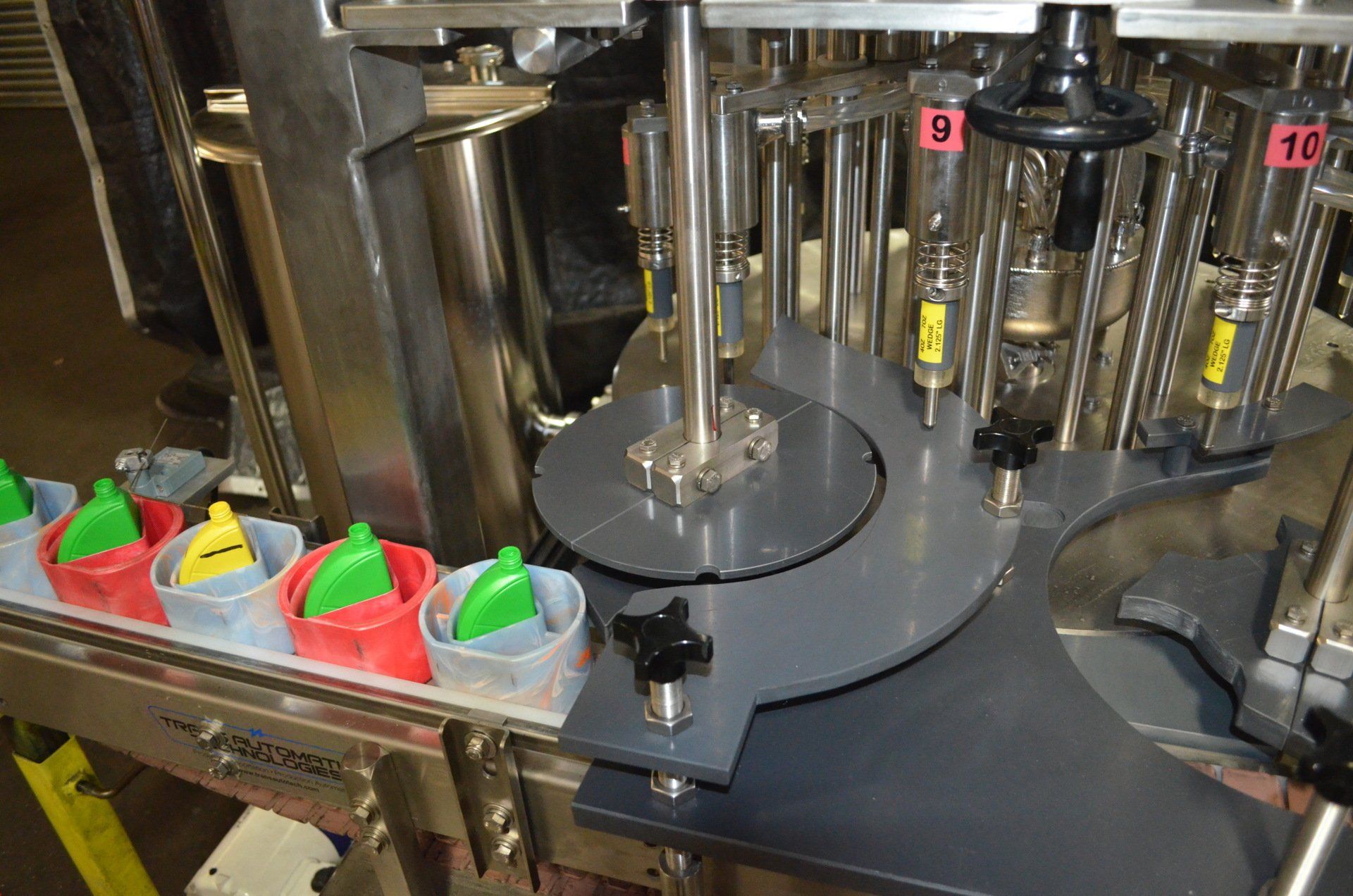

High-Speed, High-Volume Fillers

Laub/Hunt’s rotary and in-line liquid filling machines are engineered to meet the pace of modern production. Available with anywhere from 4 to 120 filling heads, these systems can reach speeds of up to 1,000 containers per minute—perfect for fast-moving, high-output operations.

Tailored Filling Technologies

Designed to handle a broad spectrum of product types and container needs, Laub/Hunt offers:

- Gravity, Pressure/Gravity, and Vacuum systems for products ranging from light juices to delicate or foamy liquids,

- Pressure metering systems for viscous or thick liquids like lotions and gels.

This flexibility ensures accurate fills across diverse industries.

Superior Build & Sanitation

Every machine is constructed with stainless steel, promoting steel hygiene and durability. The design supports food-grade and chemical-resistant applications, including corrosive products like bleach. Advanced Clean-In-Place (CIP) capabilities and washdown-ready configurations reduce downtime and reinforce operational cleanliness.

Comprehensive Turnkey Solutions

Laub/Hunt goes beyond standalone fillers, offering end-to-end packaging line integration—from bottle unscramblers and cappers to case packers and centralized controls. Their support includes customer training, instructional videos, and full-function trial runs, ensuring seamless implementation from start to finish.

Unparalleled Engineering & Service Support

With a global support infrastructure, they provide:

- Dedicated on-site start-up, commissioning, and operator training,

- Responsive field service and technical maintenance,

- Spare parts availability and system upgrades,

- Machine rebuilding and optimization services to prolong lifecycle and performance.

Standout Innovations

- Rotary Volumetric “Posifiller”: Delivers high-volume precision with speeds up to 600 cpm and tight fill accuracy.

- Rotary Liquid Fillers: Deliver up to 1,000 cpm with ±1/16" precision, coupled with flexible filling options and hygienic design features.

Why Laub/Hunt?

- Proven Longevity and Engineering Expertise

- Scalability and Configurability for Diverse Operations

- Robust Sanitary Design and Flexibility for Challenging Products

- True Turnkey Delivery with Full Lifecycle Support