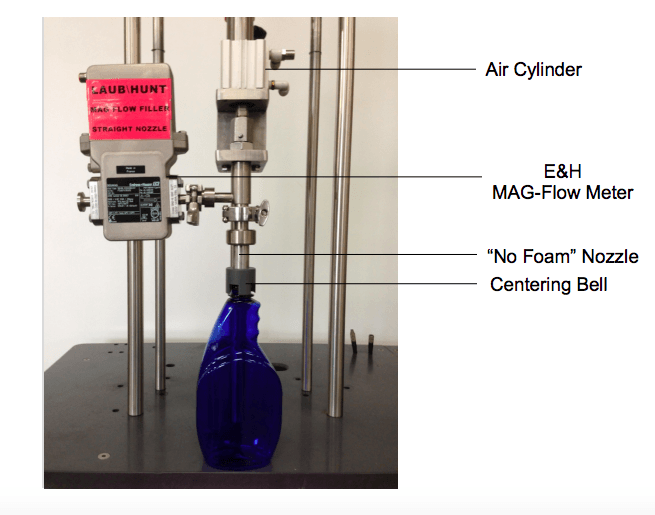

The measuring sensor consists of a lined pipe, an electromagnetic coil, and corrosion-resistant electrodes. When the conductive liquid, or product slurry, passes through the magnetic field (produced by the magmeter electronics), it generates a voltage proportional to the average velocity of the material, in another word, the voltage induced by the flowing fluid is proportional to the flow rate. The measuring electrodes detect the voltage signal which is sent to an amplifier where it is digitized and communicated to the transmitter. The transmitter processes the signals, outputs current and pulse signals which are used to determine a pre-set fill volume. Liquid media can be accurately measured with conductivities of 1µS/cm and above on Laub\Hunt Mag-Flow

fillers. Fill accuracy is +/- 1/2 of 1 percent or better.