Efficiency and Sustainability: Eco-Friendly Bottle Filling Solutions

Efficiency and Sustainability: Eco-Friendly Bottle Filling Solutions

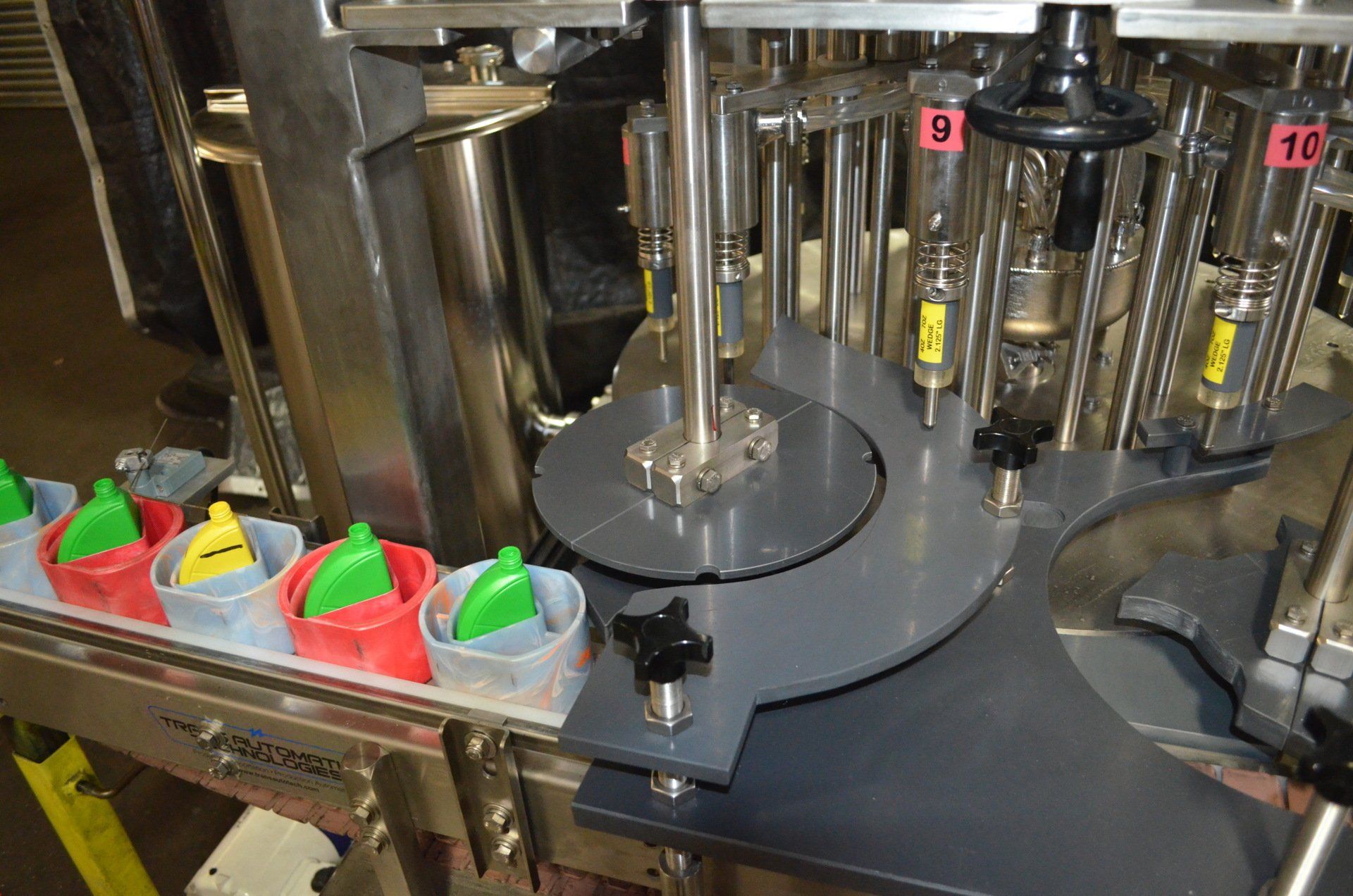

The growing demand for environmentally responsible production methods has driven significant innovation in bottle filling solutions. Today, companies are adopting advanced eco-friendly bottle filling equipment designed to balance operational efficiency with sustainable practices. These solutions not only benefit the environment but also contribute to improved productivity, reduced costs, and enhanced brand reputation.

Key Elements of Eco-Friendly Bottle Filling Solutions

Eco-friendly bottle filling systems focus on energy-efficient technology and resource conservation. They are built to reduce waste, streamline operations, and minimize carbon emissions. Equipment optimized for sustainability uses less water, electricity, and compressed air while delivering consistent results. Automated features allow for precise filling with minimal spillage, further reducing resource consumption.

Sustainability in packaging also plays a major role. Many modern systems are designed to work with biodegradable or recyclable bottles, ensuring compatibility with green packaging initiatives. This helps companies meet consumer expectations for sustainable products and comply with industry regulations aimed at reducing plastic waste.

The Role of Automation in Eco-Friendly Production

Automation plays a critical role in sustainable bottle filling solutions. Automated equipment not only increases the speed and precision of operations but also ensures that resources are used efficiently. Advanced sensors monitor fill levels, temperature, and pressure to prevent overuse of materials, while Clean-in-Place (CIP) technology eliminates the need for manual cleaning, reducing water and chemical consumption.

Automation also reduces downtime, optimizing energy use during production cycles. With smart control panels and remote monitoring capabilities, operators can identify and resolve issues quickly, further enhancing efficiency.

Benefits of Eco-Friendly Bottle Filling Solutions

Eco-conscious filling solutions deliver multiple benefits, including lower production costs. By minimizing waste and energy consumption, companies reduce operational expenses while improving profitability. Additionally, businesses that adopt green technology appeal to environmentally aware consumers, strengthening brand loyalty and market presence.

These sustainable systems also ensure compliance with environmental regulations. Reducing emissions, waste, and water usage helps businesses avoid fines and improve their standing with regulators, contributing to a cleaner production process overall.

Embrace Sustainability and Efficiency Today

Eco-friendly bottle filling solutions make it possible to align environmental goals with operational performance. They offer a path toward sustainable growth while maintaining high levels of efficiency and product quality.

Take the next step in building a greener future for your business. Contact us today to explore our innovative range of eco-friendly bottle filling equipment, designed to help you reduce waste, conserve resources, and stay ahead in a competitive marketplace.