Enhance Your Overflow Filler Performance with the NZ-1500-SS Titanium/PVC Nozzle

Enhance Your Overflow Filler Performance with the NZ-1500-SS Titanium/PVC Nozzle

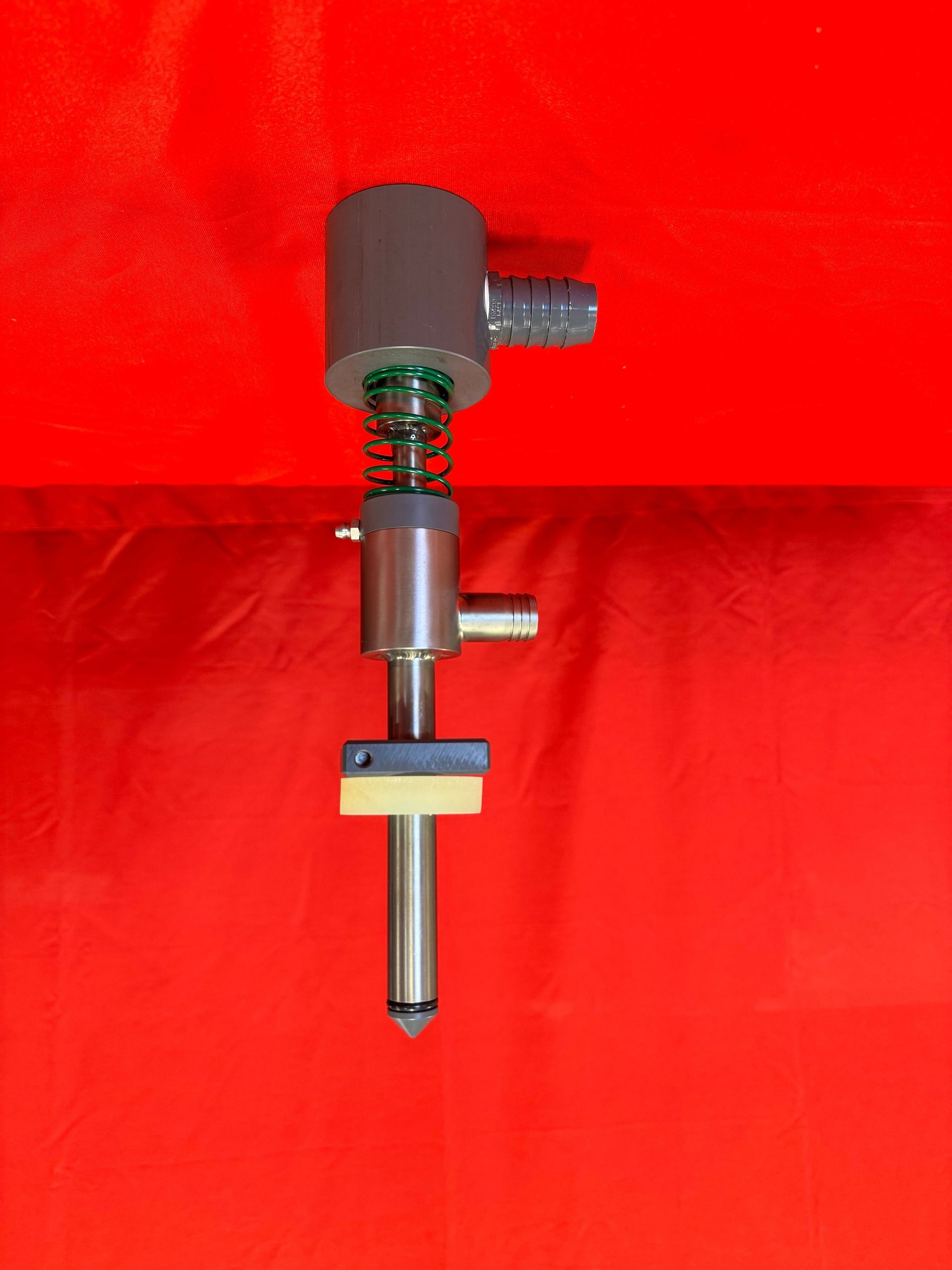

If you're working with bleach or other corrosive liquids, choosing the right nozzle can make all the difference in maintaining efficiency, accuracy, and product integrity. Laub/Hunt’s

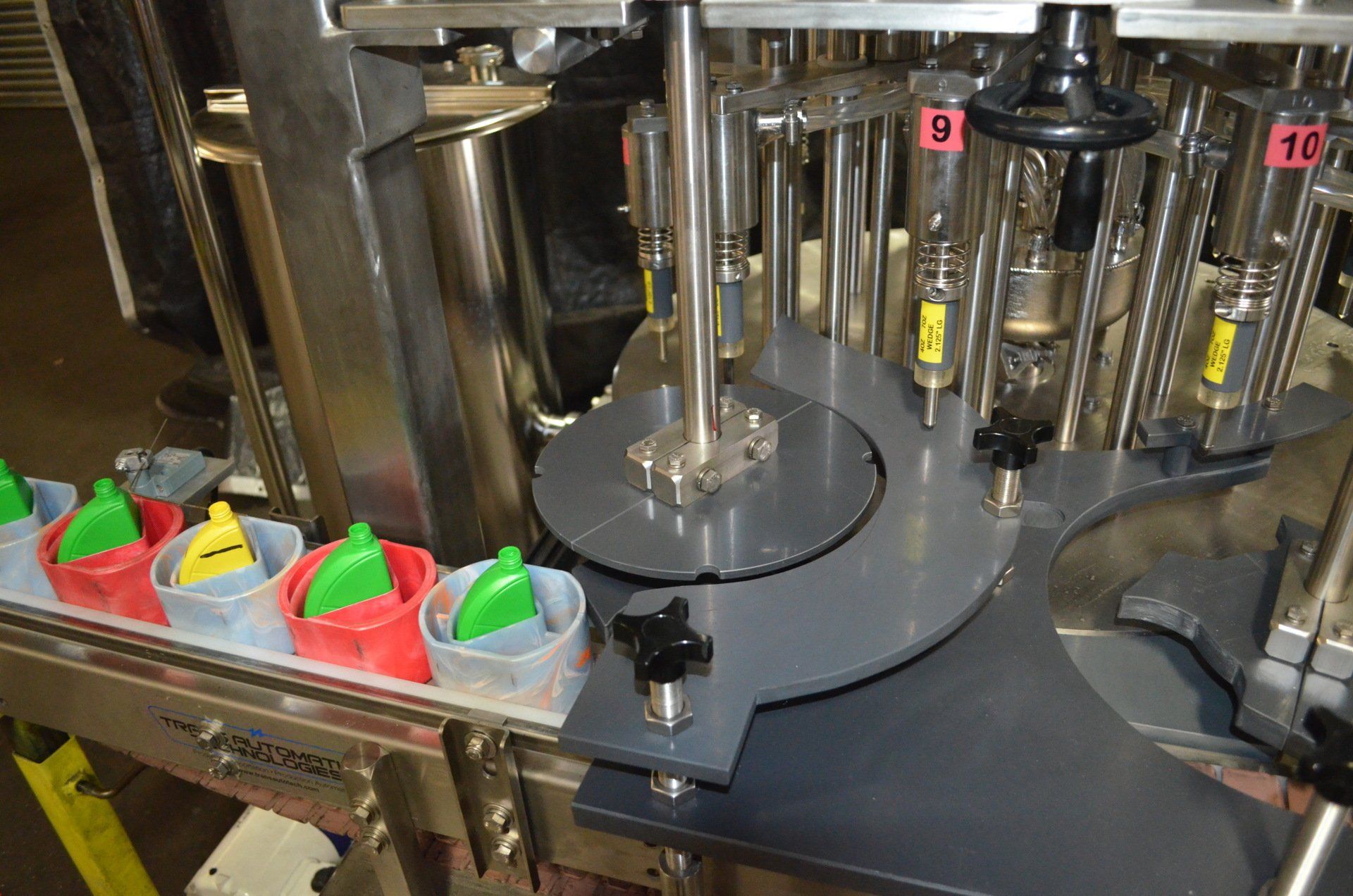

NZ-1500-SS .700" Titanium/PVC Nozzle is designed specifically for high-precision applications and is fully compatible with Laub/Hunt overflow fillers.

This premium nozzle is crafted from

titanium and PVC, making it ideal for demanding environments and aggressive chemical products. With a 28 mm neck finish and durable construction, it ensures long-term performance while helping reduce downtime and maintenance costs.

Key Features of the NZ-1500-SS Nozzle:

- Precision Filling: Optimized for bleach and other corrosive products where clean, consistent fills are critical.

- Durable Materials: Titanium resists corrosion and wear, while PVC helps ensure chemical compatibility.

- Smart Design: 1” product inlet and ¾” return allow for reliable flow and control during every cycle.

- Adjustable Flow Rate: Allows customization based on production speed and product type.

- Ready for Use: In stock and ready to ship—no long lead times.

Why It Matters

For companies in the cleaning product, chemical, and personal care industries, bleach filling can be one of the more challenging tasks on the production line. Standard nozzles simply won’t hold up over time, especially when dealing with harsh chemicals. The NZ-1500-SS nozzle delivers not only precision but also chemical resistance, minimizing product waste and reducing machine wear.

Request a Quote

Laub/Hunt’s NZ-1500-SS nozzle is available now. To get pricing and learn more about integrating this nozzle into your production line, request a quote today or contact the Laub/Hunt sales team for more details.